Automation & Controls

Automation & Controls

INTEGRATED SOLUTIONS

Origin’s Automation and Controls team develops a wide range of control system solutions that are tailored for our customer’s specific needs. These can be complex robotic armatures, full-scale production lines down, retrofitting manual systems with remote capabilities, and everything in-between. We employ a robust and diverse suite of hardware and software, all with the intention of providing the most powerful and cost-effective controls solution possible for your specific needs. We offer our capabilities as needed or as an integrated solution that includes control system design, programming, fabrication, and both physical and electrical integration.

- Control System Design

- Programmable Logic Controller (PLC) integration and programming

- User Interface design and programming

- Distributed Control Systems for large scale controls

- Full System Monitoring and Data Acquisition

- Hardware selection, configuration, and integration

- Control Panel Design and Manufacturing

- Documentation as required, including one-line drawings, electrical schematics, I/O lists, BOMs, etc.

- Electrical system installation and integration

- Microcontroller Programing

Engineering

ORIGIN employs a wide range of engineers to provide for all your engineering needs, whether it be structural, mechanical, or electrical.

All of our engineers receive extensive hands-on training with our fabrication team and machinists. This gives them a unique understanding of how to produce designs that are not only creative, but also scalable and cost effective for our customers. Our wide range of expertise, extensive software suite, and practice of working closely with our fabrication team, ensures that you receive the most practical and effective solution every time.

STRUCTURAL

focuses on the framework of structures, and on designing those structures to withstand the stresses and pressures of their environment and remain safe, stable and secure throughout their use.

MECHANICAL

Engineering that combines engineering physics and mathematics principles with materials science to design, analyze, manufacture, and maintain mechanical systems. It is the division of engineering that involves the design, production, and operation of machinery.

ELECTRICAL

Electrical engineers design, develop, test, and supervise the manufacture of electrical equipment, such as electric motors, automation and navigation systems, communications systems, or power generation equipment. Electrical engineers also design the electrical systems of various vehicles.

ENGINEERING

STRUCTURAL ENGINEERING

Origin structural engineers are adept at the application of code and have years of design experience to provide you with the most efficient and effective structural solutions available.

- PE Stamping (All states)

- Structural Engineering Consulting

- Finite Element Analysis Simulation

- Fatigue & Physical Testing

- Load Testing

- Independent Engineering

- Construction engineering

- Field inspection

ENGINEERING

MECHANICAL ENGINEERING

Origin mechanical engineers work closely with you and our team of fabricators to create efficient, effective, and buildable designs that meet all your needs for motion, flow, containment, and any other mechanical or mechatronic need.

- Pneumatic and hydraulic design

- Robotic equipment design

- Mechatronic design for automation and lifting equipment ROV’s

- Process control

- Value engineering

- Large mechatronic lifting equipment ROV’s

- Tooling and process assistance and design

- Custom tooling solutions

- Finite Element Design

ENGINEERING

LOAD TESTING & SIMULATION

Load testing and understanding the behavior of structural lift systems are very important to the origin team. Our in-house load testing verification and the ability to calibrate our calculations before and after load tests make our approach accurate and validated.

- Calibrated Load Testing Per ASME

- Structural inspection on lifting equipment

- Lifting equipment design

- Below the hook design

- Load certification and documentation

- Finite Element Simulation calibration to loads

ENGINEERING

FIELD & INSPECTION SERVICES

Our engineers are available for in-depth site review and document inspection, ensuring that construction and installation go as smoothly and correctly as possible.

- Geotechnical inspection

- Foundation reinforcement inspection

- ACI concrete inspection

- Structural inspection

- Construction management support

- Owners engineering support

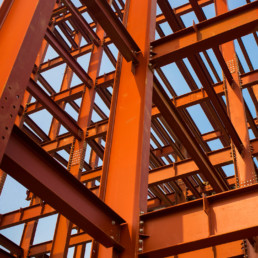

Fabrication

ORIGIN FABRICATION

Origin Fabrication will build to specification or solve your challenges and meet your specific needs

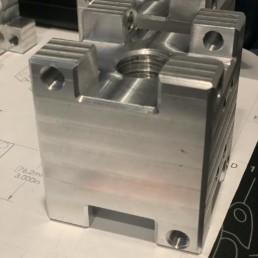

We offer our capabilities as needed, which include fast lead times and quality production. The ORIGIN fabrication team has the ability to work at a rapid pace with a team of engineers behind it. This gives us the flexibility to ensure that everything that ORIGIN produces can be customized to suit our customer’s specific needs. Our practical experience in the fabrication world has differentiated the ORIGIN fabrication team. Our approach on manufacturing utilizes fixturing to allow for cost optimization and component quality. With decades of combined experience in structural and non-structural fabrication, we have delivered projects ranging from long structural lifting beams to small custom mechanical equipment.

WELDING APPLICATIONS

MIG – Gas Metal Arc Welding (GMAW)

TIG – Gas Tungsten Arc Welding (GTAW)

Stick – Shielded Metal Arc Welding (SMAW)

Flux-cored – Flux-cored Arc Welding (FCAW)

TECHNICAL PRECISION

Our precision metal fabricators cut, bend, form and assembles precise metal parts. Piecing together a puzzle, the fabrication team produces specialized components at very high tolerances